DN House: Manufacturing Dynamics Proves a Machining Company Can Start with Just $300

2023.10.11

Back in 2014, three people used $100 each to buy used laptops. They started renting time on other shops’ machine tools at night, while holding onto their existing 9-to-5 jobs.

Today, Manufacturing Dynamics (Madison Heights, Michigan) has their own facility, their own machines and more work than they know what to do with. How did they get here? Let’s find out.

The humble beginnings

Randall Tamm (President), Derrick Tamm (Vice President) and Jonathon Tamm (Vice President of Business Development) all had different expertise. One had an engineering background, one had manufacturing and one had purchasing. With such a natural fit for their own manufacturing endeavor, the squad figured they had nothing to lose and created a side hustle.

They rented machine time at first, and by spending so much time on a wide range of equipment, the trio came to realize what really mattered when it was time to buy their own.

Eventually, after diligently putting in the work after hours, they realized it was time to go in full-time.

A shop of their own

“Over time, we saved our money and bought a premises,” Randall said. “Bought used machines and did well enough with them. When it was time to buy new ones, we ran the gamut to try to find the right ones. DN Solutions came out on top.”

The parts Manufacturing Dynamics made initially started with wood, plastics and aluminum. As their time and capability increased, they added design and engineering to the mix. Today, they provide engineering services for molds, holding fixtures, clamping, trimming tools and machine fixtures.

A mantra inside the building is There’s nothing we can’t build, and Manufacturing Dynamics customer base can attest to that. Rivian is the recipient of custom-made wrenches, holding fixtures for prototype builds and body and white tooling. Tooling for aerospace, lighting fixtures and holding clamping systems for automotive, and heavy industry parks are all a daily part of the mix as well.

A shop of their own

“Over time, we saved our money and bought a premises,” Randall said. “Bought used machines and did well enough with them. When it was time to buy new ones, we ran the gamut to try to find the right ones. DN Solutions came out on top.”

The parts Manufacturing Dynamics made initially started with wood, plastics and aluminum. As their time and capability increased, they added design and engineering to the mix. Today, they provide engineering services for molds, holding fixtures, clamping, trimming tools and machine fixtures.

A mantra inside the building is There’s nothing we can’t build, and Manufacturing Dynamics customer base can attest to that. Rivian is the recipient of custom-made wrenches, holding fixtures for prototype builds and body and white tooling. Tooling for aerospace, lighting fixtures and holding clamping systems for automotive, and heavy industry parks are all a daily part of the mix as well.

The DN difference

Manufacturing Dynamics very first brand-new machine purchase came in 2021 with the arrival of the DNM 5700L. Right away, it was obvious to the Tamms that it was the correct call.

“The machine is unique, capable of doing longer parts,” Randall said. “High rigidity that was beyond our expectations. It outputs the accuracies we need. It truly did help us to become more dynamic.”

“We always knew DN was a good brand,” Derrick said. “The DNM holds positions well with nice rigidity. We get plenty of travel in X and Y, and we’re now running faster than when we started. We actually had to purchase different tooling so we could keep up with the DNM.”

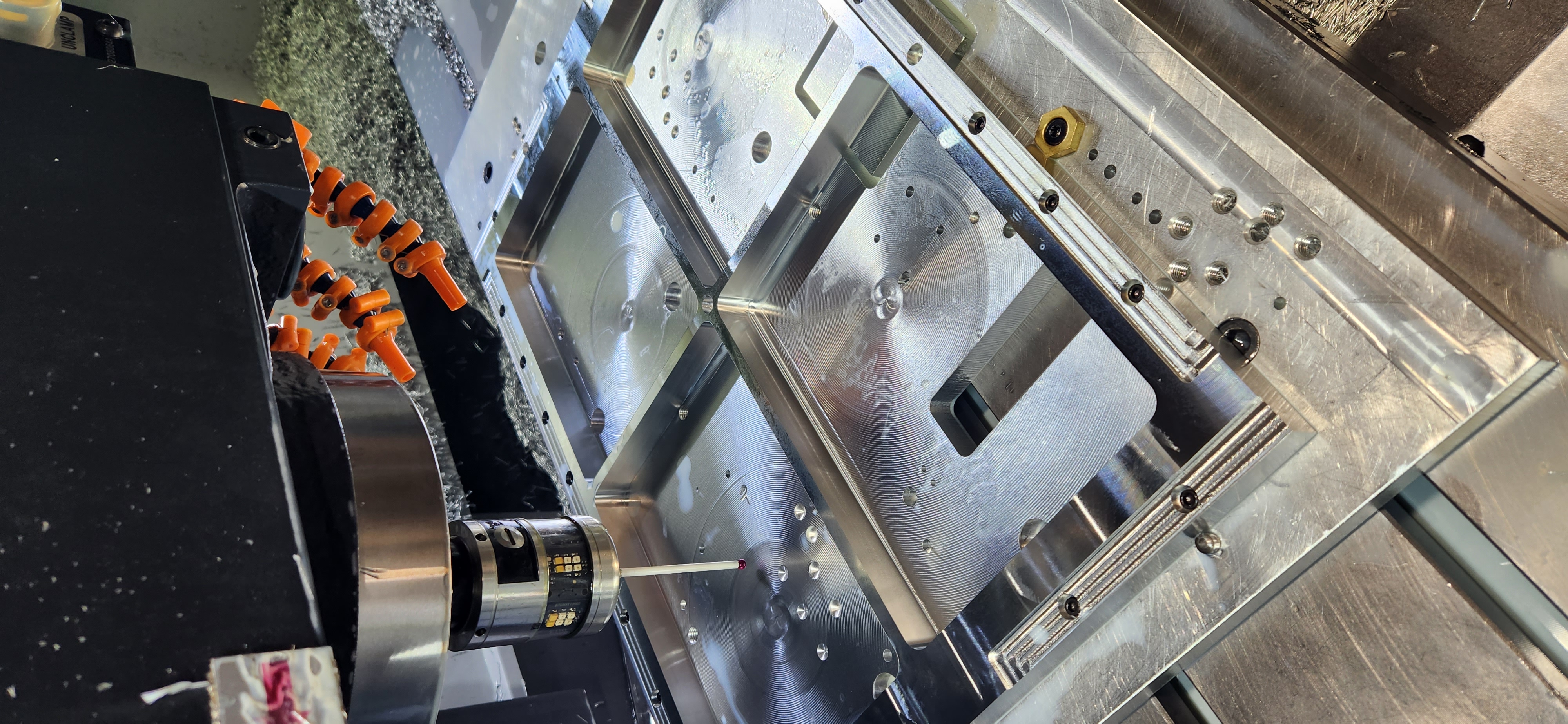

DN machine #2 was purchased at IMTS 2022 in Chicago: the recently-debuted BVM 5700. It’s the high end of DN’s vertical machining center portfolio.

“Because it was new, we didn’t know a lot about the BVM,” Randall said. “But we knew the bridge structure was intriguing.”

“We again did a lot of research, and it showed that the accuracy of this style of machine was ideal for the mold work we do,” Derrick said. “Our local distributor was adamant about the machine’s quality, and credit to him, the BVM has been incredibly accurate for us.”

The third and final DN machine to join the Manufacturing Dynamics party was the DEM 4000, a tiny but mighty VMC that brings ridiculous value—and is ideal for new hires to learn on.

“We added the DEM because the price is so good for the features you get. The footprint, cost and value are tremendous,” Randall said. “It’s definitely outperformed, and we’d love to pick up another one.”

“We’re putting it through the ringer for sure,” Derrick said. “Mostly running smaller parts, but using the entire bed.”

The DN difference

Manufacturing Dynamics very first brand-new machine purchase came in 2021 with the arrival of the DNM 5700L. Right away, it was obvious to the Tamms that it was the correct call.

“The machine is unique, capable of doing longer parts,” Randall said. “High rigidity that was beyond our expectations. It outputs the accuracies we need. It truly did help us to become more dynamic.”

“We always knew DN was a good brand,” Derrick said. “The DNM holds positions well with nice rigidity. We get plenty of travel in X and Y, and we’re now running faster than when we started. We actually had to purchase different tooling so we could keep up with the DNM.”

DN machine #2 was purchased at IMTS 2022 in Chicago: the recently-debuted BVM 5700. It’s the high end of DN’s vertical machining center portfolio.

“Because it was new, we didn’t know a lot about the BVM,” Randall said. “But we knew the bridge structure was intriguing.”

“We again did a lot of research, and it showed that the accuracy of this style of machine was ideal for the mold work we do,” Derrick said. “Our local distributor was adamant about the machine’s quality, and credit to him, the BVM has been incredibly accurate for us.”

The third and final DN machine to join the Manufacturing Dynamics party was the DEM 4000, a tiny but mighty VMC that brings ridiculous value—and is ideal for new hires to learn on.

“We added the DEM because the price is so good for the features you get. The footprint, cost and value are tremendous,” Randall said. “It’s definitely outperformed, and we’d love to pick up another one.”

“We’re putting it through the ringer for sure,” Derrick said. “Mostly running smaller parts, but using the entire bed.”

The Dynamics difference

Being such a young and fresh shop has its advantages. Manufacturing Dynamics favors digital over print and being as nimble as possible. They also believe strongly in fully training new hires and not holding back, starting from CAD and moving to programming, machining and inspection.

That philosophy has proven to be attractive to the younger generation, and because Manufacturing Dynamics has worked with county and state to be a certified apprentice center, the shop has quickly become one of Michigan’s best places to start a manufacturing career.

“We take on college students with no experience and teach them everything we know,” said Randall. “Right now, we have three manufacturing engineering apprentices. We try to pave the way for a new generation of manufacturing, and the way that we work helps us to do that.”

Manufacturing Dynamics favors collaboration over egos, and it knows that the next great idea can come from anywhere. It’s a fast-moving and adaptable culture that has proven to be magnetic for young and hungry manufacturers.

The Dynamics difference

Being such a young and fresh shop has its advantages. Manufacturing Dynamics favors digital over print and being as nimble as possible. They also believe strongly in fully training new hires and not holding back, starting from CAD and moving to programming, machining and inspection.

That philosophy has proven to be attractive to the younger generation, and because Manufacturing Dynamics has worked with county and state to be a certified apprentice center, the shop has quickly become one of Michigan’s best places to start a manufacturing career.

“We take on college students with no experience and teach them everything we know,” said Randall. “Right now, we have three manufacturing engineering apprentices. We try to pave the way for a new generation of manufacturing, and the way that we work helps us to do that.”

Manufacturing Dynamics favors collaboration over egos, and it knows that the next great idea can come from anywhere. It’s a fast-moving and adaptable culture that has proven to be magnetic for young and hungry manufacturers.

Forecasting the future

“Growth would be the word,” Randall said. “We currently have more demand than we can handle. So expanding our facility, growing to 30 employees and beyond in the next couple years. And of course, adding equipment to fill the needs.”

Time will tell if those three DN machines welcome additional siblings to the floor, but one thing is certain: we’ll be there should the need arise. If you need the kind of ROI bump that only comes with purchasing an elite performance-per-dollar machine, you know what to do. Talk to DN Solutions America or get in touch with your expert local distributor.

Forecasting the future

“Growth would be the word,” Randall said. “We currently have more demand than we can handle. So expanding our facility, growing to 30 employees and beyond in the next couple years. And of course, adding equipment to fill the needs.”

Time will tell if those three DN machines welcome additional siblings to the floor, but one thing is certain: we’ll be there should the need arise. If you need the kind of ROI bump that only comes with purchasing an elite performance-per-dollar machine, you know what to do. Talk to DN Solutions America or get in touch with your expert local distributor.